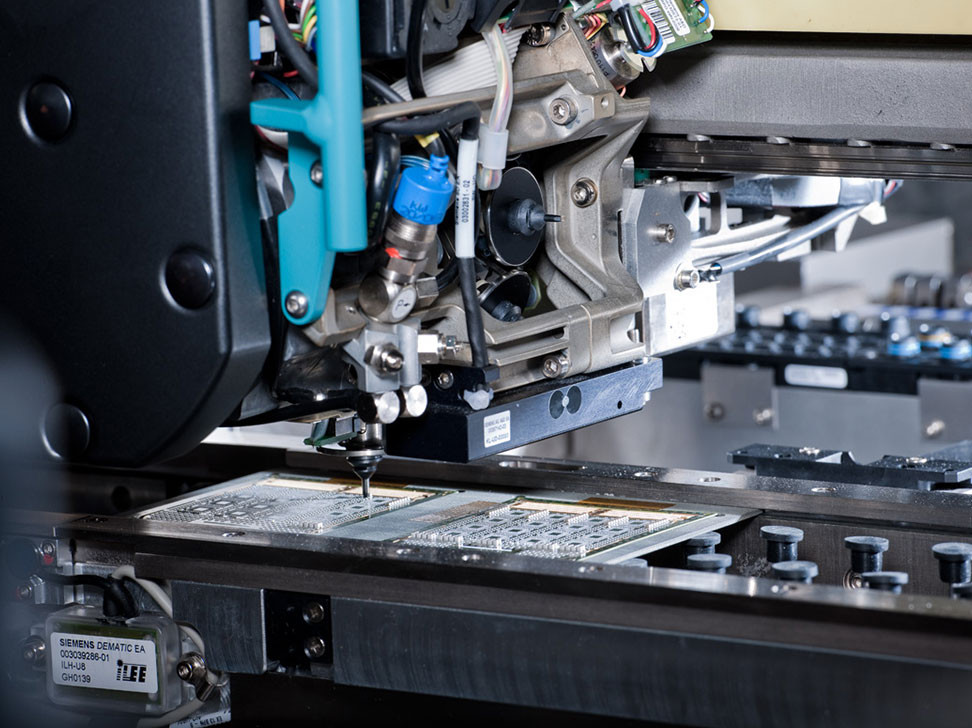

Our state-of-the-art SMT production lines guarantee the precise assembly of electronic components. The process begins with solder paste printing. A stainless steel template ensures the solder paste is placed exactly where it should be. The solder paste application is then automatically checked optically. High-precision placement machines then place SMT components up to size 01005 onto the PCB.

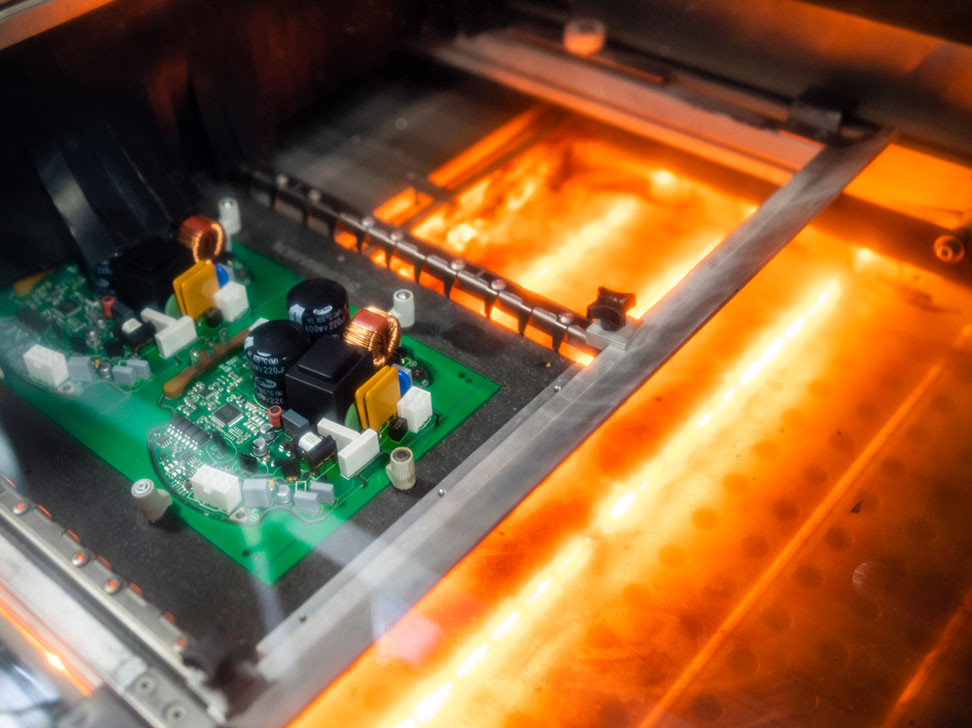

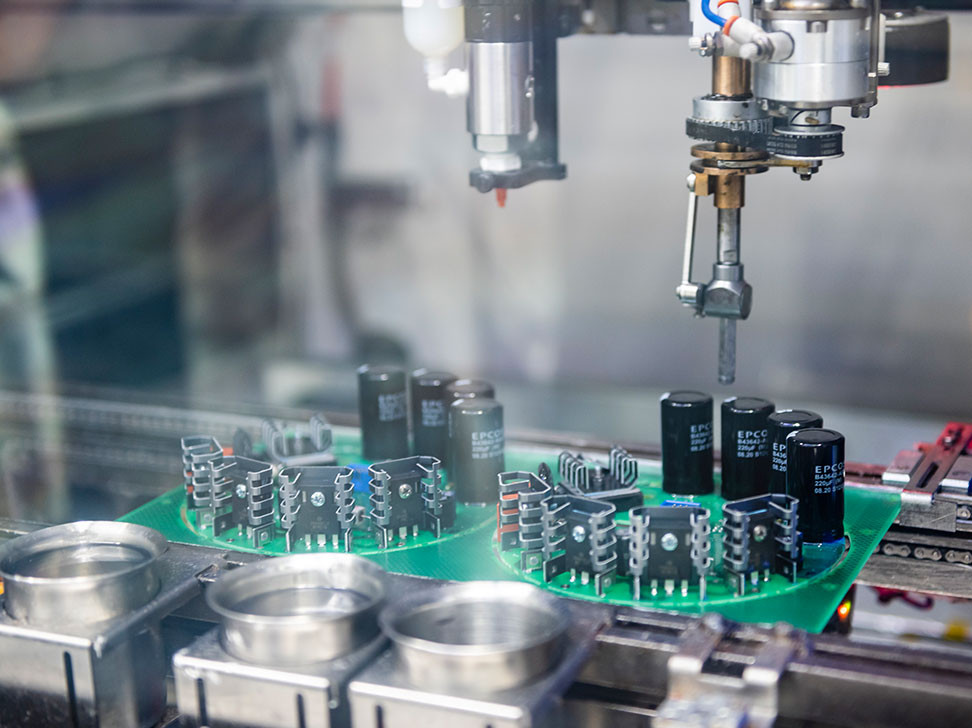

Before soldering, we carry out an inspection to ensure the components are correctly positioned and oriented. Reliable soldering takes place in the reflow oven. An automatic optical inspection follows to ensure the highest soldering quality.